As the demand for modular and prefab housing continues to grow worldwide, space capsule homes have emerged as one of the most innovative solutions for resorts, glamping sites, hotels, and commercial accommodation projects. But what exactly makes a space capsule different from traditional prefab houses? And how are these futuristic units manufactured in a factory?

In this article, we take you inside the space capsule product design and factory production process, showing how high-quality capsule homes are built from structure to finish.

What Is a Space Capsule Home?

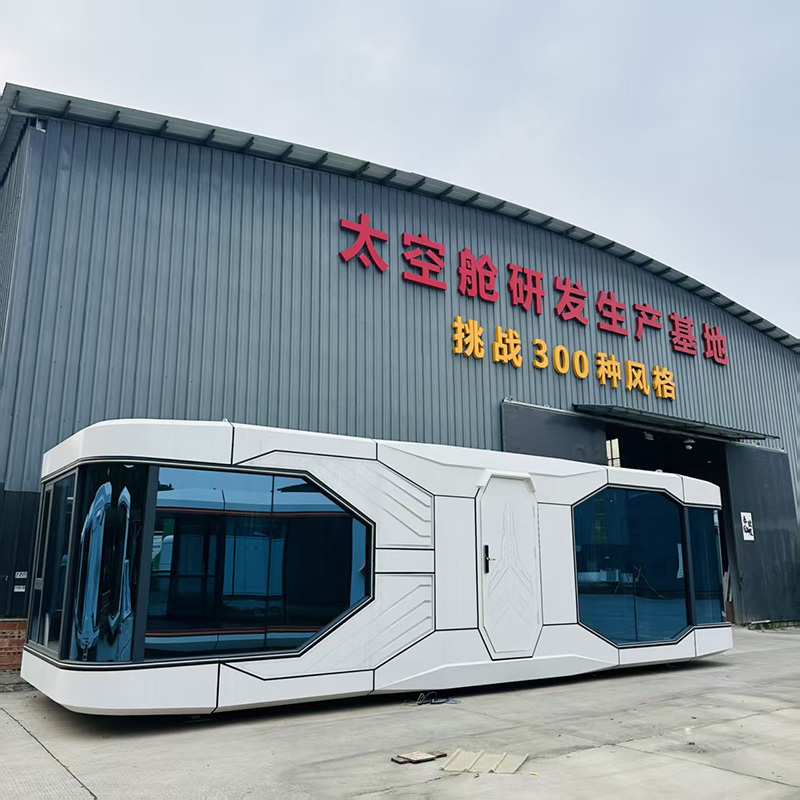

A space capsule home is a factory-prefabricated modular living unit inspired by aerospace design. Unlike conventional container houses, space capsules focus on streamlined appearance, premium interiors, and integrated systems, offering a hotel-level living experience in a compact footprint.

Space capsules are widely used for:

Luxury glamping resorts

Boutique hotels and eco-lodges

Rental cabins and Airbnb projects

Staff accommodation and remote sites

With plug-and-play installation, they can be deployed quickly while maintaining consistent quality.

Structural Design: Built for Strength and Durability

Every space capsule begins with a high-strength galvanized steel frame. The structure is engineered to ensure:

Long service life (20–30 years)

Excellent wind resistance

Stable performance in various climates

All steel components are precision-cut and welded in the factory, ensuring accuracy that is difficult to achieve with on-site construction. This structural integrity is the foundation of the capsule’s safety and durability.

Factory Production Process: Quality Starts on the Line

1. Steel Frame Fabrication

The production process starts with the fabrication of the main steel structure. Each frame is assembled on a dedicated production line, inspected for welding quality, dimensional accuracy, and load-bearing performance.

2. Exterior Panel Installation

After the frame is completed, exterior panels made of aluminum alloy or coated metal sheets are installed. These panels are designed to be:

Weather-resistant

Corrosion-resistant

Visually seamless

The smooth, futuristic appearance of a space capsule is achieved through this factory-controlled installation process.

3. Insulation & Thermal Performance

High-performance insulation materials such as PU foam or rock wool are applied to walls, roof, and floor. This ensures:

Energy efficiency

Comfort in hot and cold climates

Reduced noise transmission

Factory insulation guarantees uniform thickness and performance across every unit.

Customization & Smart Systems

Space capsules are not one-size-fits-all. Depending on project requirements, we offer customization options such as:

Interior layout adjustments

Furniture and color schemes

Smart lighting and control systems

Panoramic windows or skylights

Each customization is incorporated during production, ensuring compatibility and reliability rather than after-install modifications.

Pre-Installation Testing & Quality Control

Before delivery, every space capsule undergoes:

Electrical system testing

Water and drainage checks (if bathroom is included)

Door, window, and sealing inspection

This pre-delivery inspection ensures the unit arrives ready for installation, reducing on-site work to simple placement and utility connection.

From Factory to Site: Fast Deployment

Once production is completed, the space capsule is shipped as a finished unit. On-site installation typically requires:

A simple concrete or steel foundation

Crane placement

Utility connection

In many cases, a space capsule can be operational within hours of arrival.

Why Factory Production Matters

Compared to traditional construction, factory production of space capsules offers:

Consistent quality

Faster project timelines

Lower labor dependency

Better cost control

For developers, resort owners, and investors, this means predictable delivery and faster return on investment.

Conclusion

Space capsule homes represent the future of modular living, combining innovative design, factory precision, and commercial practicality. From steel structure fabrication to interior finishing, every step of the production process is designed to deliver a reliable, high-quality living unit that performs well in real-world projects.

If you are planning a glamping resort, hotel expansion, or modular accommodation project, a space capsule offers a smart and scalable solution. Please feel free to contact us for a best quotation any time.